SPONGE JET-BLASTING

This softer abrasive blasting option is an absolute game changer and with an incredible range of applications. Our professional team brings the equipment and expertise to complete the job quickly with a minimum of disruption. Contact us today at (631) 655-8700 for a free consultation on how Sponge-Jet blasting can solve your stripping, prepping, restoration, and cleaning needs.

What is Sponge-Jet Blasting?

Benefits of Sponge-Jet Blasting

Less Dust

Quicker Set-up and Clean-up

Because Sponge-Jet blasting produces so little dust, the containment requirements are minimal compared to other types of blasting. Our team can quickly set up, perform the work, and clean-up. The foam projectiles and surface contaminants can be easily and quickly vacuumed up. There is no wastewater to contain, collect, and dispose of as hazardous waste. This means minimum disruption to your business and the public.

Environmentally-Friendly Restoration Service

The EPA conducted extensive testing on Sponge-Jet media and found it far superior to traditional blasting media. Sponge-Jet blasting is an environmentally responsible way to strip and prep because the sponges can be recycled and used again. It is an eco-friendly and green choice for blasting and stripping.

Safe Around Sensitive Equipment

Economical Abrasive Blasting

You would expect to pay a premium for the benefits of Sponge-Jet blasting services. However, you will be pleasantly surprised to discover that Surface Resto’ Sponge-Jet blasting service is comparable in cost to our other traditional blasting media. This is possible for several reasons:

• Lower Labor Costs – Sponge-Jet blasting requires fewer labor hours for a start-to-finish project.

• Lower Freight Costs – The sponges are far lighter than sand or soda. We do not pay as much in freight costs, and we pass that savings on to you.

• Reusable Sponges – The sponges can be reused up to fifteen times. This allows us to vacuum them up and reuse them immediately on your job, which substantially reduces the amount of media required and saves you money.

Give Surface Resto a call at (631) 655-8700 to find out how we can restore your surfaces with Sponge-Jet blasting.

Applications for Sponge-Jet Blasting

Surface Resto provides a low-cost and efficient option when any part of the job requires stripping or blasting. The low-dust, low-ricochet features of Sponge-Jet allow it to be used on almost any site. Many customers have even found that they could obtain blasting permits for Sponge-Jet, where they could not get a sand-blasting permit. Whatever your stripping, cleaning, restoration, or surface profiling needs, Sponge-Jet blasting has you covered. Below are a few of the proven applications for foam-based abrasive blasting:

Industrial Equipment Projects

Sponge-Jet blasting has grown in popularity as an efficient method of cleaning industrial equipment. The flexible scheduling offered by Surface Resto means that you can schedule our team at your convenience to address your surface preparation needs. Our quick set-up minimizes disruptions, and the low-dust process also allows your craftsmen to continue their work while we blast. Avoid costly delays and call Surface Resto to solve your surface preparation needs quickly.

Coating Preparation Projects

It is estimated that inadequate surface preparation is responsible for up to 75% of coating failures. The increased visibility during the dustless Sponge-Jet blasting process also helps the operator review the finished surface before coating. To avoid the waste and unnecessary costs associated with coating failure, use Surface Resto’s Sponge-Jet blasting to get it done right the first time.

Restoration Projects

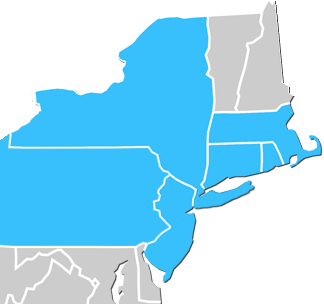

About Surface Resto

- New York

- New Jersey

- Connecticut

- Rhode Island

- Massachusetts

- Pennsylvania

Call us at (631) 655-8700 to talk to a Surface Resto professional about how Sponge-Jet blasting can solve your restoration, stripping, prepping, and surface cleaning needs.

Get in Touch!

Request a Quote

[gravityform id=”1″ title=”true”]

@SurfaceResto 2021 copyright