PAVER CLEANING & SEALING

Many of our customers ask if it is necessary to seal pavers and the answer is yes; concrete pavers should always be sealed. Although paving stones are manufactured with the highest quality cement, cement is corrosive and as such will wear over time from sun, rain, cold and other conditions. A good sealing job consisting of an experienced Long Island paver sealing professionals and quality products will create a protective coating over the cement. This coating makes the stones water-repellent and weather-proof to protect the surface from corrosion for many years.

As a professional Long Island paver cleaning and sealing company, we understand that pavers should always be pressure washed before they are sealed. It is extremely important that the surface of the pavers are clean; after the sealer is put on, any stains or materials underneath will not be reachable. At Surface Resto, we use a high volume, low pressure, hot water pressure washer to remove all stains and dirt from the pavers prior to sealing them.

There are various types of sealers that are manufactured, but the best sealers for paving stones are water-based urethanes; this type of sealer is environmentally safe, not harmful to vegetation and VOC-compliant throughout the entire United States. In addition, they allow superior joint stabilization.

The professional paver sealing professionals at Surface Resto only use the highest level appropriate products for each Long Island paver sealing job. In addition to the type of sealer, it must be determined what type of sand material should be used to fill the joints between the pavers. The answer is polymeric sand because polymeric sand will not leave stains on the surface.

Our Long Island paver sealing experts ensure that the sand tightly wills the joints and hardens completely. We always sweep off the excess sand on the pavers before wetting the sand to prevent the glue from smudging onto the paver surface. The urethane sealer used by our professionals also helps the sand to harden and prevents ants or other insects from digging into the pavers and weeds from growing through them.

In addition to the type of sealer, it must be determined what type of sand material should be used to fill the joints between the pavers. The answer is polymeric sand because polymeric sand will not leave stains on the surface.

PAVER CLEANING & SEALING

We recommend that pavers should not be sealed until at least one year after they are installed so they can “cure” through a four-season cycle of weather. This will remove most of the lime from the paver’s surface. Once cleaned and pressure washed, the remaining lime will be removed, exposing the true color of the stone. Once sealed, the color will be preserved that way.

Sealer manufacturers typically recommend that pavers be re-sealed every three to five years to restore the sheen. However, once sealed the first time, the sealer will penetrate the stone and prevent the pavers from edging for many years.

Surface Resto is a team of experts in paver cleaning and sealing on Long Island. Our professionals are knowledgeable and experienced in their field and are ready to help you protect the pavers outside of your home or office from maximum appearance and enjoyment.

Get in Touch!

Send us an email. We are always happy to help you.

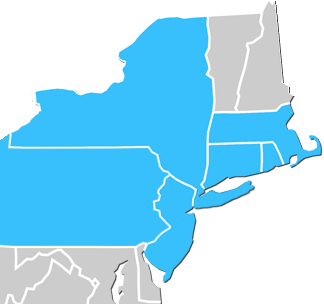

- New York

- New Jersey

- Connecticut

- Rhode Island

- Massachusetts

- Pennsylvania

Request a Quote

@SurfaceResto 2021 copyright