Dry Ice Blasting Services

Dry ice blasting has become increasingly popular for its environmentally friendly and efficient cleaning capabilities, particularly in industrial settings such as pharmaceutical and food processing plants. This method offers numerous benefits across various industries and applications.

In industrial cleaning, dry ice blasting effectively removes contaminants like grease, oil, adhesives, and other residues from machinery and equipment, ensuring optimal performance without the risk of damage or wear. In the pharmaceutical industry, maintaining a sterile environment is crucial. Dry ice blasting helps remove contaminants without introducing moisture or chemicals, reducing the risk of contamination and ensuring compliance with stringent hygiene standards.

For food processing plants, cleanliness is paramount to ensure food safety. Dry ice blasting effectively cleans equipment and surfaces, removing bacteria, mold, and other contaminants. Since it doesn’t leave behind any residue or moisture, it prevents microbial growth and reduces the risk of foodborne illnesses.

Dry ice blasting uses solid carbon dioxide pellets that sublimate on contact, transitioning from solid to gas without leaving any secondary waste, making it an eco-friendly alternative to traditional cleaning methods that generate hazardous waste or require chemical solvents.

One of the key advantages of dry ice blasting is its ability to clean without the need to disassemble equipment. This significantly reduces downtime and labor costs associated with cleaning. Additionally, since no drying time is required, equipment can be put back into operation immediately after cleaning.

Dry ice blasting is non-abrasive, meaning it doesn’t damage delicate surfaces or precision components. This makes it suitable for a wide range of applications, from cleaning sensitive electronic equipment to restoring historical artifacts. By reducing downtime, labor costs, and the need for chemical cleaners, dry ice blasting can be a cost-effective cleaning solution for many industries. It also extends the lifespan of equipment by providing thorough and gentle cleaning.

This results in reduced downtime for your business. There are also no hazardous chemicals, solvents or media; just a small amount of carbon dioxide which is already all around us. That makes dry ice blasting perfect for the food and medical industries where there can be no contamination.

Also, due to the non-abrasive nature of dry ice blasting, it can quickly remove most contaminates from equipment without damage to sensitive components like switches, wiring, panels, tubes, or belts.

Rather than using hard, abrasive media to grind on a surface, dry ice blasting uses soft dry ice, accelerated at supersonic speeds, and creates mini-explosions on the surface to lift old paint, dirt, grease and other particles off the underlying substrate.

When the dry ice pellets hit the target, the surface temperature quickly decreases and the velocity of the pellets causes the undesirable materials to be removed.

Give us a call at (631) 655-8700, send us an email at surfaceresto@gmail.com,

What is Dry Ice Blasting?

Dry ice blasting is a process in which solid CO2 pellets are accelerated through a blasting nozzle using compressed air. Upon impact, the CO2 pellets sublimate (change from a solid to a gas) and lift the dirt, grime, and other contaminants from the surface being cleaned.

Benefits of Dry Ice Blasting

- Non-abrasive: Dry ice blasting does not damage or wear down the surface being cleaned, making it ideal for delicate machinery and equipment.

- Eco-friendly: Dry ice blasting does not use any chemicals or solvents, making it an environmentally friendly cleaning solution.

- Fast and efficient: Dry ice blasting can clean surfaces quickly and effectively, reducing downtime and increasing productivity.

- Versatile: Dry ice blasting can be used on a variety of surfaces, including metal, plastic, and wood.

Get in Touch!

Send us an email. We are always happy to help you.

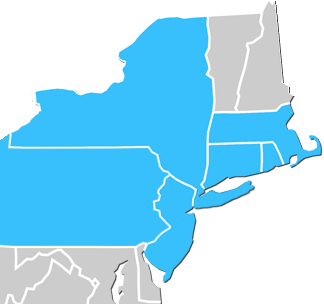

- New York

- New Jersey

- Connecticut

- Rhode Island

- Massachusetts

- Pennsylvania

@SurfaceResto 2021 copyright